Design without constraints

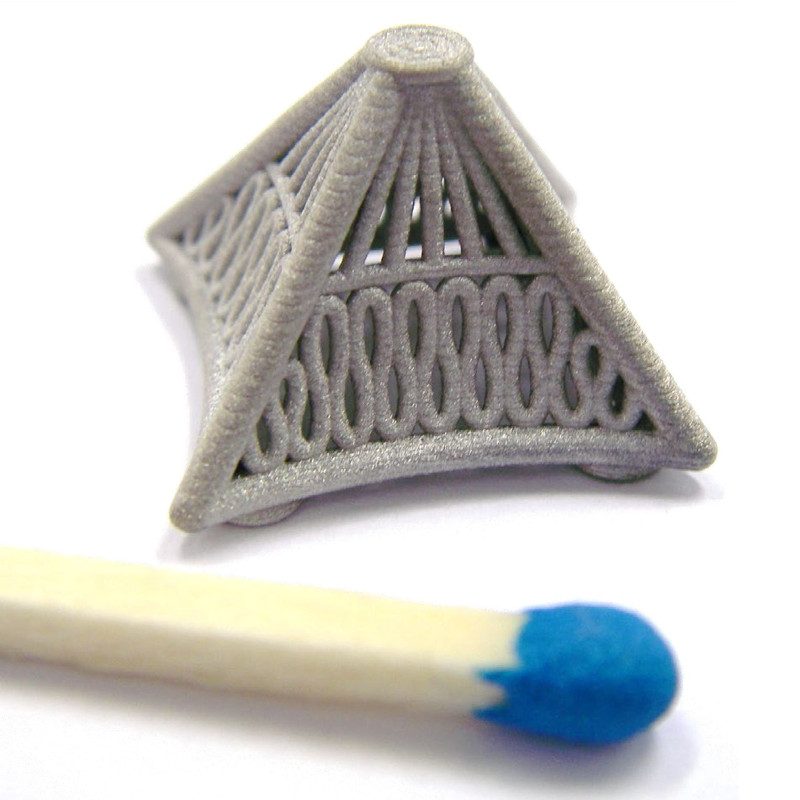

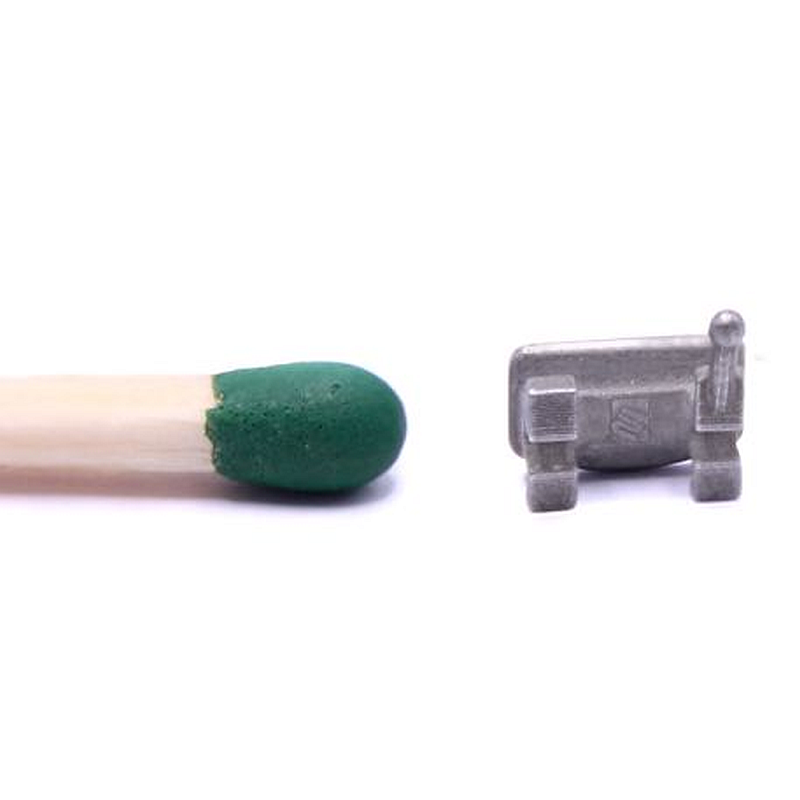

Lithography-based Metal Manufacturing produces high-precision metal components with excellent surface quality. The stereolithographic process combined with the absence of printing supports result in detailed, smooth surfaces with great design freedom.

The absence of internal stress in green parts allows printing extremely thin wall geometries.

Iterate prototypes faster

The combination of resolution, accuracy and surface quality often eliminates the need for post-processing and machining operations. You can iterate designs faster and lower your costs, including MIM mold rework costs.

No need for tooling

The LMM technology is not limited to prototypes and customized products. It can be used for low volume serial production at zero tooling cost.

We provide a wide range of finishing and inspection services for production.

Technical Capabilities

-

Capabilities

-

Design guidelines

| US | Metric |

|---|---|---|

Max. Part Dimensions | 2.75 x 1.77 x 3.93 in. | 70 x 45 x 100 mm |

XY Resolution | 0.0014 in. | 35 µm |

Z Layer Height | 0.0004 - 0.0024 in. | 10 - 60 µm |

Surface Roughness | Ra 157 - 236 µin. | Ra 4 - 6 µm |

General Tolerances | ISO 2678-f | ISO 2678-f |

Not sure where to begin?

Send us a message and we’ll walk you through it.

Why choose the LMM technology?

Design flexibility

Since LMM does not require any printing supports, the design guidelines are quite simple - meaning more freedom and faster iterations.

Ultra-fine features

The stress-free green part production process allows printing extremely thin features - down to 0.004 in. (100µm)

Smooth surface finish

Green parts are produced by a photopolymerization process without application of heat, enabling high surface quality.

Speed to market

Production volumes of up to 10,000 parts per year can easily be achieved for small parts, enabling a smooth transition from prototyping to serial production.