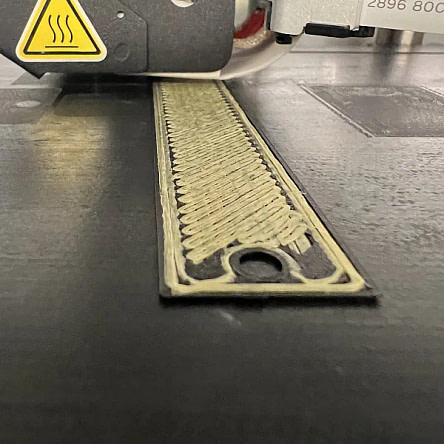

Composites and Thermoplastics

Printed for long-term performance

Sometimes performance is everything. We offer a wide range of performance composite and thermoplastic materials for durable, functional parts.

High mechanical performance

Continuous fiber reinforcement improves the stiffness and strength of your parts. It also influences other performance factors such as abrasion and temperature resistance, fatigue and impact behavior, and heat conductivity.

We offer the full range of Markforged materials and will help you select the right combination of base materials and reinforcement fibers for your application. We can also use simulation software to validate the performance of a custom fiber layout before printing parts.

Custom thermoplastics

We offer FDM/FFF printing services with a wide range of thermoplastic materials, in dimensions up to 1,170x1,120x1,200mm (46x44x47.2in.). If you need a specific grade or color that we don't offer as a standard, we can usually source it and develop matching printing profiles with short lead time.

We also print materials with density modifiers (foaming agent or fillers) for CT scanning fixtures.

Standard Materials List

ABS

ABS (Acrylonitrile Butadiene Styrene) thermoplastic parts have high impact resistance. They are lightweight and have good dimensional stability, making them suitable for a wide range of applications as long as they are not exposed to heat and UV sources.

ASA

ASA (Acrylonitrile Styrene Acrylate) is often considered as a UV-resistant alternative to ABS. It has similar impact and toughness properties and is preferred in outdoor applications.

LW-PLA

LW-PLA is foamed PLA. Its low density and good dimensional stability makes it a material of choice for industrial CT scanning fixtures. LW-PLA is also a popular material in drones and RC airplanes.

PA6-CF

PA6-CF (Polyamide 6 carbon fiber) offers high strength and stiffness, along with good thermal resistance. It can be used alone with short fiber reinforcement, or combined with continuous fiber reinforcement on Markforged printers (Onyx family of materials with carbon, Kevlar or glass fibers). Chemical compatibility and UV exposure must be reviewed with care.

PC

PC (polycarbonate) parts have high impact resistance and good dimensional stability. They have a high temperature resistance and good electrical insulation properties, making them suitable for electronic and electrical applications. They are also UV resistant which makes them suitable for outdoor applications. PC offers relatively low chemical and UV resistance.

PEKK

PEKK (Polyetherketoneketone) is known for its high thermal resistance, high strength and stiffness, and excellent chemical (not UV) resistance. Its use is limited by its high material cost.

PETG

PETG (polyethylene terephthalate glycol) offers flexibility, transparency, and impact resistance. It is easy to process and has a relatively low cost, making it a popular material choice for very large parts.

PLA

PLA (Polylactic Acid) has good dimensional stability, good mechanical properties for its weight, low cost, and is easy to process. This makes it a popular material in design validation applications. Its low temperature, chemical and UV resistance limits its durability in harsh environments.

PP

PP (Polypropylene) parts are lightweight, strong, and resistant to chemicals and high temperatures. They have good impact resistance and can be easily molded into various shapes and sizes. They have low moisture absorption and are often used in packaging, consumer goods, and automotive applications.

TPU

TPU (Thermoplastic Polyurethane) parts have a high level of flexibility, high abrasion resistance and good tear resistance. They are generally resistant to oils and fuels and to UV exposure, making them suitable for applications where resistance to harsh environments is needed.